Track the runtime (ON time) of your machines.

To track the runtime of your machines, you just need to place the tracking device to a secure location somewhere either on the surface of the machine or inside the chassis.

Always make sure to not place the tracker in place enclosed with metal as signals won't be able to make it to-from the module.

The Rocbird2 requires vibration/movement to track runtime, so make sure to place it next to the engine or any part which creates vibrations if you're planning to install the module into a stationary machine.

If you're installing it into a moving machine/vehicle just make sure that the device has signal.

In case of cleaning machines, the best approach is to combine the two and put the machine close to the brushes or vacuum motor as both of those can make vibrations in the machine, but generally the movement of the cleaning machine should be enough.

The battery lifetime depends heavily on the environment the device is in, the quality of the batteries inserted into the tracking device as well as how much the machine is used.

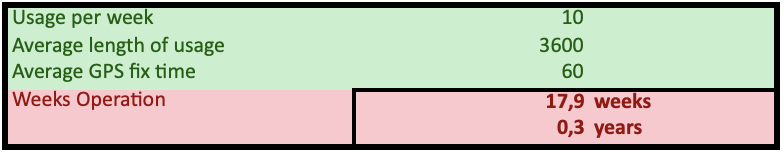

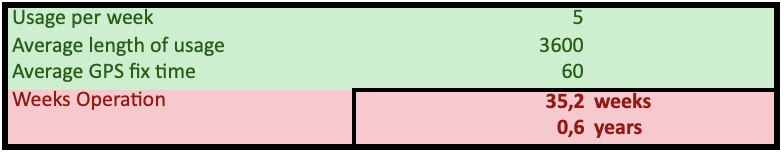

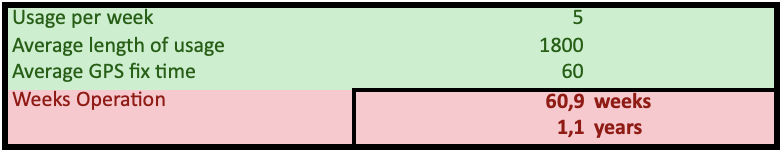

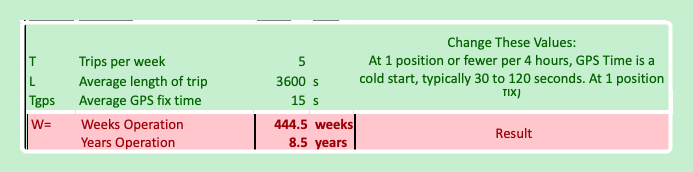

The main factors in estimating the battery lifetime are the following:

average length of usage

average GPS fix time (the time it takes for the module to acquire location depends on how good the signal is)

Here are a couple of scenarios with a battery lifetime estimation for our recommended battery.

Example of an outdoor application, where GPS position can be acquired on a 15 second average with one hour runtime on every workday.

To put down an order for this item, please write an email to orders@toolsense.io noting the item code and quantity of the required item(s).

Order Codes:

TSIOT-ROCBIRD2-BLE-RUN for Global with BLE

TSIOT-ROCBIRD2-RUN for Global without BLE